How Fluid Flexitanks Resist Abrasion and Handle Harsh Shipping Conditions

Global Bulk Liquid Transport presents a unique set of engineering challenges that traditional dry cargo rarely encounters. Unlike conventional liquid shipping containers, which often rely on rigid structures, flexitank systems must adapt to constant internal and external forces. Shipping non-hazardous liquids across oceans or continents requires more than just a large bag. Logistics managers must contend with continuous container vibration and friction against steel corrugated walls. Sea turbulence and extreme temperature variations further test the limits of packaging materials. Because any breach leads to significant product loss and environmental clean up costs, abrasion resistance remains the most critical factor in cargo safety.

Understanding Abrasion in Shipping Containers

Inside a standard 20-foot container, the internal walls are not perfectly smooth. The corrugated steel creates numerous friction points that can act like sandpaper during a long voyage. As a vessel moves through sea swells, the liquid inside a flexitank creates dynamic movement. This shifting load causes the material to rub continuously against the container interior. If the material quality is poor or the film is too thin, these friction points quickly become rupture risks. High-quality liquid shipping containers must be engineered to neutralise these mechanical stresses before they compromise the seal.

How Fluid Flexitanks Resist Abrasion

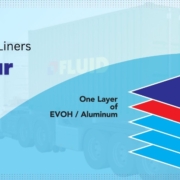

Layered Film Structure

The multi-layer inner liner evenly distributes internal pressure. Instead of concentrating stress at one point, pressure spreads across the film layers. This reduces localised strain.

Reinforced Outer Protection

The woven polypropylene outer layer shields the inner film from contact with the steel wall. It acts as a buffer against corrugated surfaces. This barrier enhances abrasion resistance during long voyages.

Seam and Valve Strength

Seams are often the weakest point in liquid shipping containers. Fluid Flexitanks use automated sealing systems and reinforced valve assemblies. Strong seam bonding prevents separation under load.

Quality Control and Testing

Abrasion resistance is validated through testing. Raw materials are inspected. Film thickness is measured. Hydrostatic pressure tests simulate full load conditions. Such quality control reduces the risk of failure during global transport.

Each of these measures contributes to structural reliability in bulk liquid shipping containers.

Handling Harsh Shipping Conditions

Sea Turbulence and Hydrostatic Pressure

When filled with up to twenty-four thousand litres, hydrostatic pressure pushes outward continuously. During sea transport, rolling motion increases dynamic loads. Flexible polyethylene stretches within safe limits.

Road Transport Shock

Truck movement introduces vertical vibration. Shock waves travel through the liquid mass. Elastic film absorbs this energy rather than transmitting it to a single stress point.

Temperature Expansion and Contraction

Liquids expand when heated and contract when cooled. Temperature shifts can stress rigid packaging. Flexible liners adjust to volume changes without cracking.

Container Stacking and Handling

Containers are lifted by cranes and stacked in ports. Sudden movements generate inertia forces. High-tensile-strength, abrasion-resistant outer layers help maintain integrity during these operations.

Flexibility and elasticity allow the tank to adapt without rupture. This resilience protects cargo and reduces claims.

Real World Applications

Abrasion resistance is vital across industries:

- Edible oils require hygienic and intact liners.

- Non-hazardous chemicals demand leak prevention.

- Syrups and viscous liquids exert high internal pressure.

- Fertilisers and industrial liquids can stress container walls.

In each case, liquid cargo transport involves continuous movement and pressure. Robust liquid shipping containers protect product value and prevent contamination.

Why Manufacturer Expertise Matters

A flexitank is only as reliable as the facility that produced it. True expertise comes from a Flexitank manufacturer in India that maintains a fully integrated facility. This means controlling every step from the extrusion of the 7-layer blown film to the assembly of the finished goods.

Compliance with global standards, such as ISO 9001, ISO 14001, and BRCGS, provides a verified layer of trust. Furthermore, a manufacturer that provides substantial product liability insurance demonstrates confidence in their engineering. Relying on material traceability and state-of-the-art testing labs ensures that the specifications on paper match the performance in the container.

Abrasion resistance is not a luxury feature but a fundamental requirement for secure bulk liquid shipping containers. Structural resilience directly protects your cargo value and your brand reputation. As you plan your next bulk shipment, remember that the material science inside the container is your first line of defense against harsh shipping conditions. Consult with engineering experts to ensure your chosen transport solution is built to withstand the rigors of the global market. Explore the specialized engineering of Fluid Flexitanks for your next secure bulk transport project.

FAQs

- Why is abrasion resistance important for flexitanks?

Friction against corrugated container walls during transit can cause ruptures. Abrasion-resistant materials ensure the tank remains intact despite constant vibration and movement.

- What materials provide the best protection against leaks?

A combination of multi-layer polyethylene (PE) for inner containment and a woven polypropylene (PP) outer shell offers the best defence against punctures and abrasions.

- Can flexitanks handle temperature shifts?

Yes, high-quality flexitanks are made from stretchable polymers that accommodate expansion and contraction caused by temperature variations during sea or road transport.

- Are Fluid Flexitanks tested for quality?

Every tank undergoes a double inspection and is tested in state-of-the-art labs to ensure compliance with international durability standards.

- What is the capacity of these shipping containers?

Flexitanks are designed to fit into standard 20-foot containers and can typically hold between 14,000 and 24,000 litres of bulk liquid.